- Technologies

- Principle of the Oxynon®

What is the Oxynon®Furnace?

- "What is the Oxynon®Furnace?"

Answer "A furnace in which there is almost no oxygen."

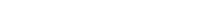

Role of the carbon materials

- Carbon materials are capable of cancelling oxygen.

- ・Oxide-based refractory bricks can not be used at temperatures above 1500℃ as they significantly lose their

relative specific strength at high temperatures.

・The carbon materials, as described in the above chart, play an important role of reacting with free oxygen inside

the furnace to cancel it in the form of CO gas.

Continuous

C/C composite belts are the important parts to realize continuous furnaces.

While a heat resistant metal belt can be used at 1150℃ or lower,Heat resistant metal belt can not be used at temperatures above 1150℃.

That is the reason why a C/C composite belt is used at high temperatures.

-

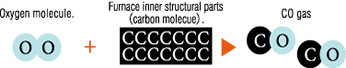

Oxidation

- Heat up iron in the air at 1000℃.

- If heated in the air at 1000℃,

iron reacts with oxygen and forms iron oxide.

Iron oxide disturbs brazing and sintering.

For efficient brazing and sintering, it is important to prevent oxidation and remove oxygen from the oxidized surface.

Reduction by use of hydrogen

- Reduce iron oxide in a hydrogen atmosphere at 1000℃.

- If iron oxide is heated at 1000℃ in a hydrogen atmosphere, hydrogen reacts with the iron oxide and reduction

reaction takes place.

The oxygen in the iron oxide and the hydrogen in the atmosphere react to cause iron oxide to return to iron and

cause hydrogen to form water.

Heat treatment in a hydrogen atmosphere basically uses this principle.

-

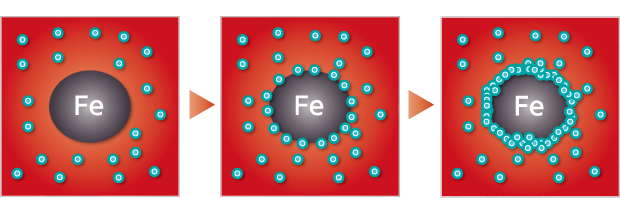

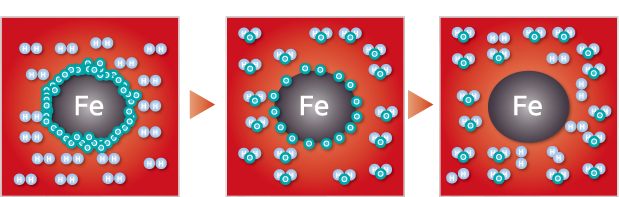

Heat dissociation (Oxynon®)

- Heat dissociate iron oxide at 1000℃ in the Oxynon®Furnace.

- Upon reduction of the oxygen content in the atmosphere to an extremely low level, the iron oxide starts to release

oxygen from its surface, which is called "heat dissociation".

Ease of heat dissociation varies with material and temperature; some are relatively easy (copper, nickel) and some

are not (aluminum).

The Oxynon®Furnace uses a carbon made muffle case to reduce atmosphere oxygen content to an extremely

low level which makes bright heat treatment possible by heat dissociation.

Application of the Oxynon®Furnace

Heat exchangers (Stainless steel, Titanium), Oil coolers (Stainless steel, Copper), EGR (Stainless steel),

Exhaust pipe (Stainless steel, Iron), Fuel tank parts (Stainless steel, Iron), AC control valves (Brass, Copper),

Porous metal (Secondary battery electrode), Fuel cell separator (Graphite),Sintered products (SiC, Sialon),

Non-oxide ceramics.

Exhaust pipe (Stainless steel, Iron), Fuel tank parts (Stainless steel, Iron), AC control valves (Brass, Copper),

Porous metal (Secondary battery electrode), Fuel cell separator (Graphite),Sintered products (SiC, Sialon),

Non-oxide ceramics.

- In-house R&D equipment

- Maximum operating temperature 2400℃

Variety of testing is available.

- Advantages of the Oxynon®Furnace

- ・Oxygen partial pressure inside the furnace can be reduced to 10 exp.-20 or lower to heat dissociate even a

difficult-to-reduce metal oxide.

・Regular pressure inside the furnace prevents metal evaporation.

・Uniform temperature distribution is available.

・Increased production capacity is available.

・Maintenance is easy.